State-of-the-art manufacturing with complex 5-axis milling capabilities and experience of bench top assembly. Our philosophy from the beginning has been to establish long-term client relationships by providing only the highest quality products paired with exemplary customer service. The latest technology in high-speed machine tools and robotic loading allow Skyline to achieve on time delivery at a competitive price.

-

Full aerospace-grade compliance with repeatable, traceable processes.

-

Precision machining of complex geometries and tight tolerances in one setup.

-

24/7 production capacity for faster turnaround and reduced costs.

-

Specializing in titanium, aluminum alloys, and high-strength steels.

-

ITAR compliant and actively pursuing CMMC certification.

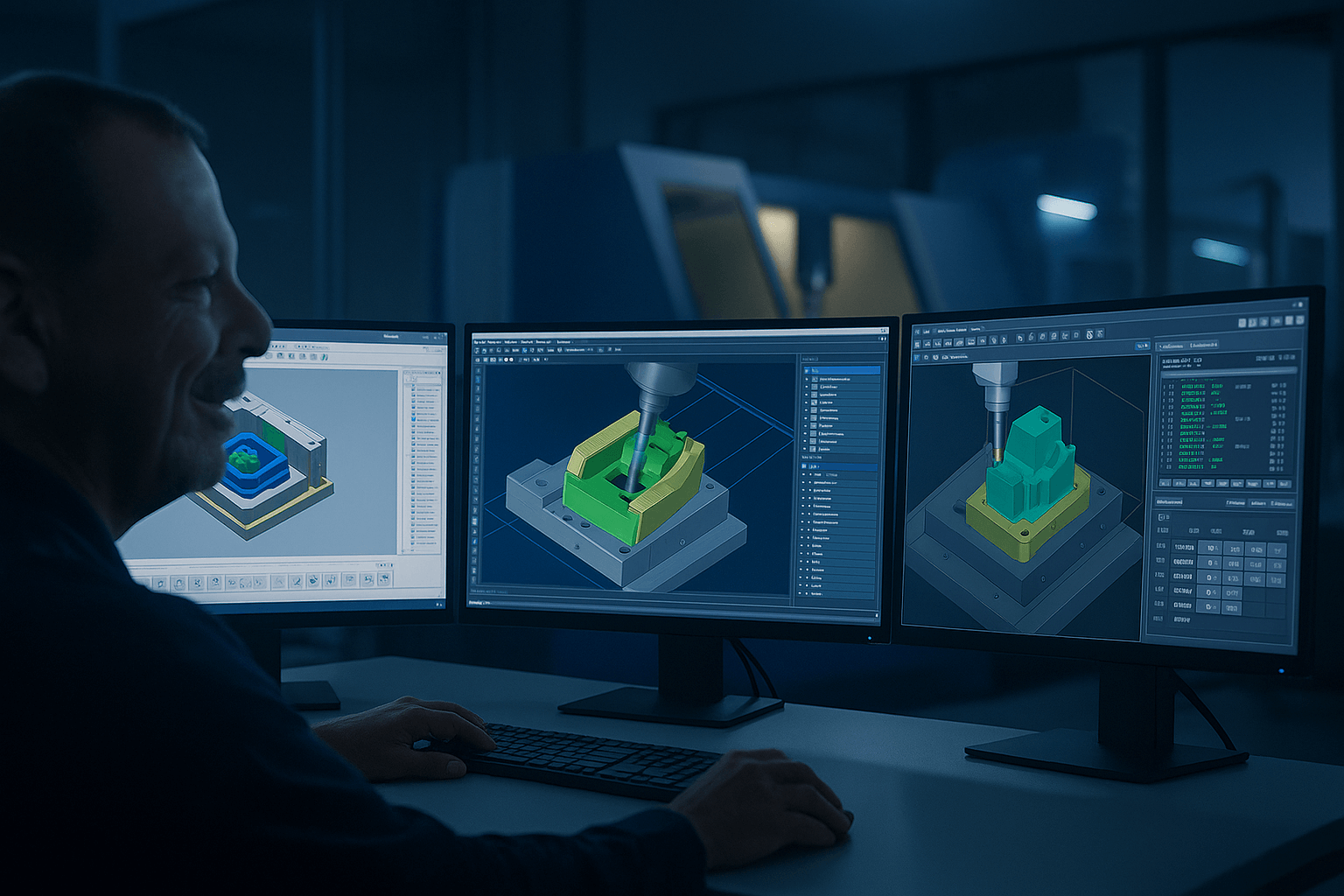

Programming

Catia V5 full CAD/CAM

Vericut

OpenDMIS

SolidWorks

Esprit

Fusion360

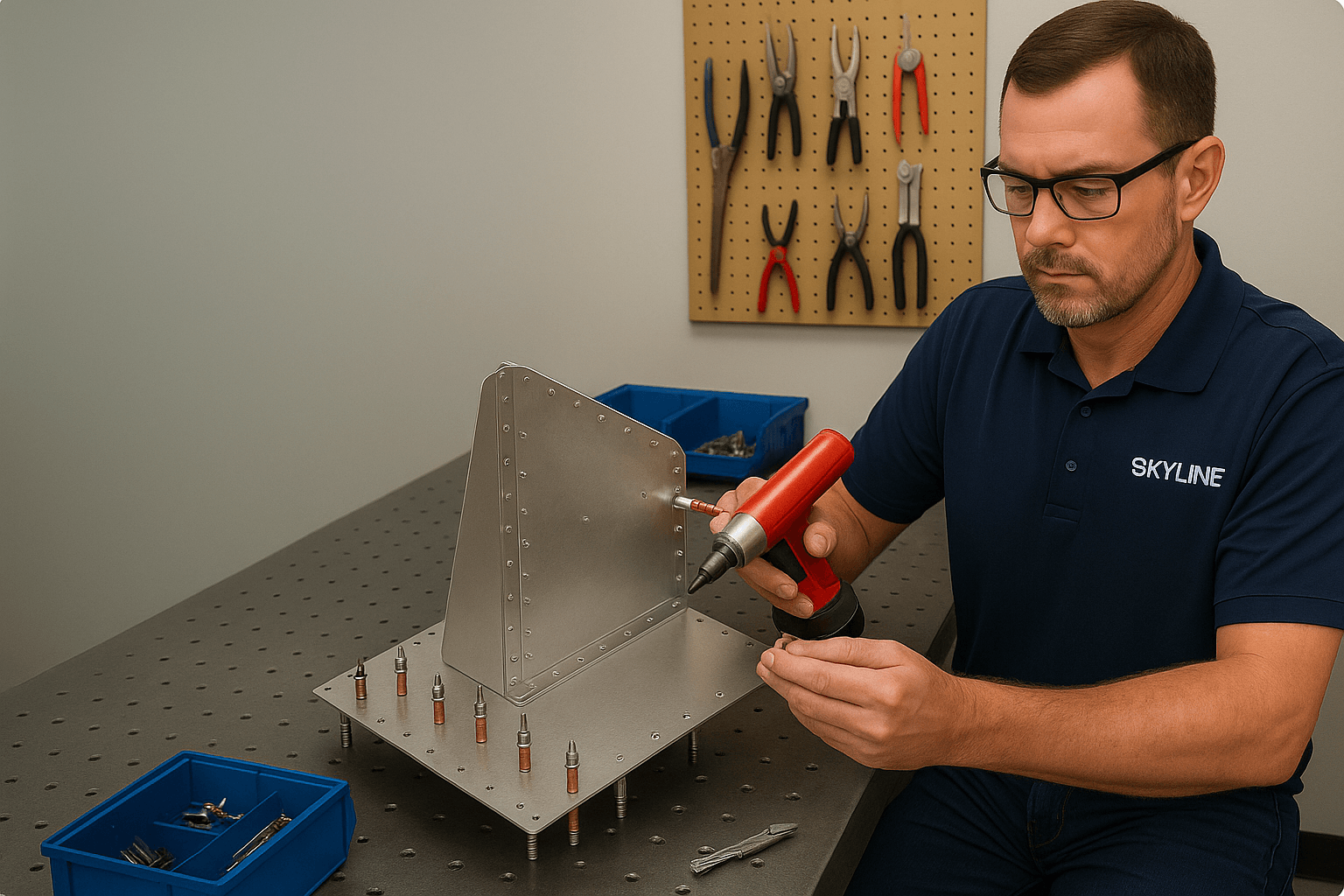

Bench Top Assembly

Rivet & nut plate installation

Click bond Certified

Bearing installation and swaging

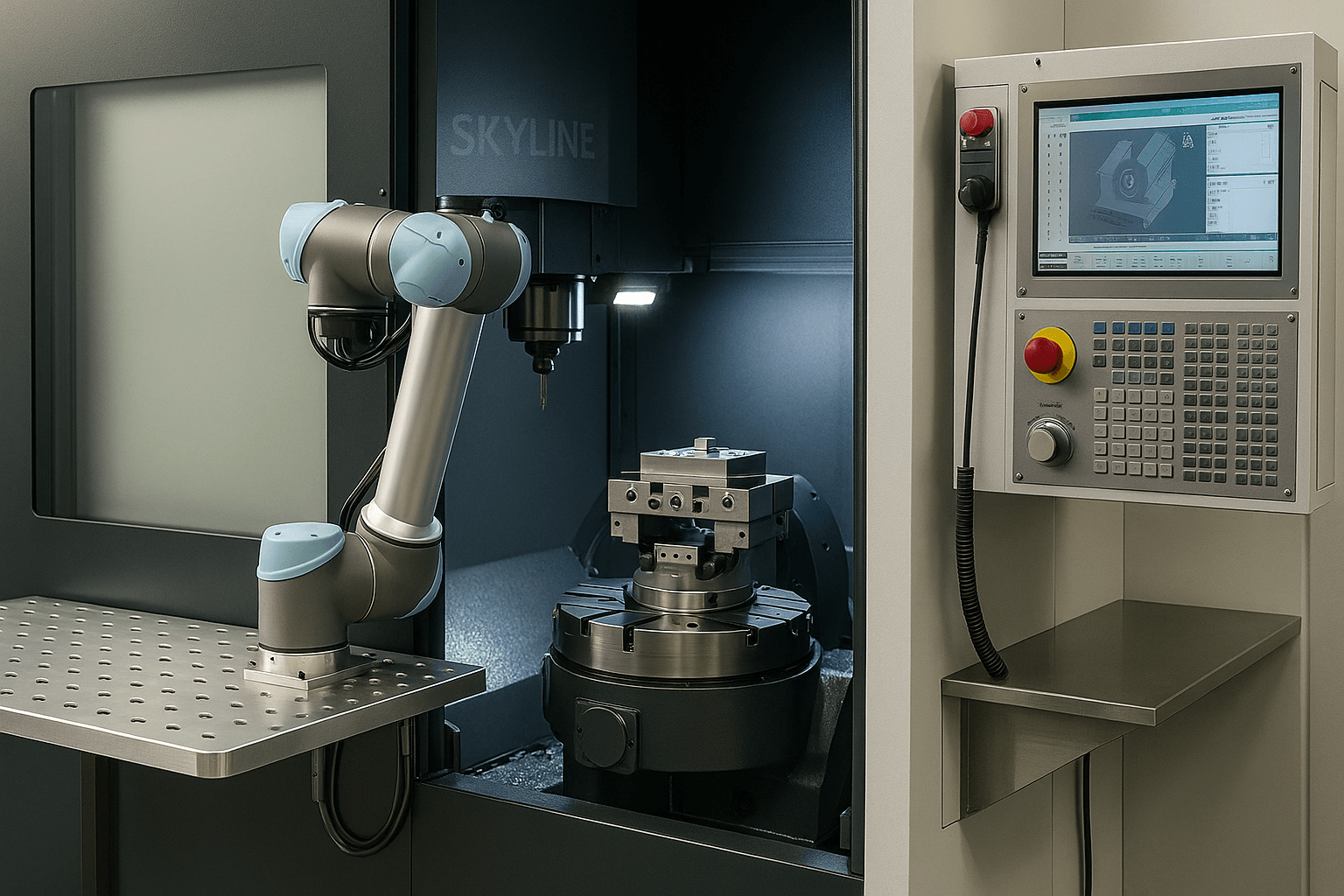

Detail Machine Work

Haas umc750ss

5-axis “lights out” production

Pick & place robotic arm for parts <10lbs

15,000 RPM

Matsuura mam75-42v (2)

5-axis “lights out” production

48 pallets, 300mm

20,000 RPM

Grob G750

Highly dynamic horizontal 5-axis milling machine

2 pallet changer, 800mm

16,000 RPM

Toyoda fa450S (4)

4-axis “lights out” production

60 pallets, 450mm

15,000 RPM